Touch scroll wheel simplifies complex user interfaces on microwaves and ovens

“When you walk into a retail store and take a quick look at home appliances, you’ll see that simple appliances such as ovens and microwaves now have very complex user interfaces. Appliance manufacturers have added innovative operating modes to better prepare delicious dinners, but these functions require many buttons to control.

“

When you walk into a retail store and take a quick look at home appliances, you’ll see that simple appliances such as ovens and microwaves now have very complex user interfaces. Appliance manufacturers have added innovative operating modes to better prepare delicious dinners, but these functions require many buttons to control.

A wall oven or microwave has more than 25 buttons to control all the functions built into the appliance, which is commonplace for consumers, but also daunting, and many functions require multiple keystrokes to operate.

The advent of touch wheel technology has simplified the complex user interface of microwave ovens and ovens. This first article in this series presents several approaches to reveal how capacitive touch sensors can help home appliance designers meet the challenges of user interface design.

Simplify common functions

The first step to making a device easier to use is to reduce the steps to activate commonly used functions. Entering a cooking time or setting a baking temperature often takes several steps, and many devices use a numeric keypad to perform this task. What if the keystroke input process could be reduced to a single touch and drag interaction?

The touch wheel detects the position around the finger by measuring the change in the capacitance of several sensing electrodes. The touch wheel is great for entering parameters because the user can simply touch anywhere on the wheel and drag their finger clockwise or counterclockwise to increase or decrease a value. The end result is a reduction of a few keystrokes to a one-click operation.

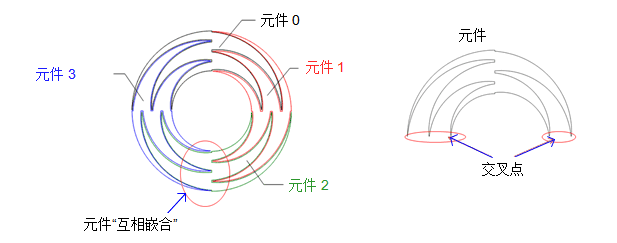

Figure 1 shows the pattern geometry of a typical touch wheel. As shown, there are 4 identical sensing elements on it, which can be mounted on the copper area of the printed circuit board. The sensing elements are fitted into each other. As the finger moves clockwise or counterclockwise on the scroll wheel, it reduces the surface area overlap between the finger and the current sensor and increases the surface area overlap between the finger and the next adjacent sensor. Changes in surface area result in measurable changes in element capacitance. Changes in capacitance between touch wheel elements are processed by software into touch positions.

Figure 1: Capacitive touch wheel sensor

performance and reliability

Microcontrollers (MCUs) such as the MSP430FR2676 are ideal for using high-resolution touch scroll wheels in devices for the following reasons:

・ Parallel measurement of up to four electrodes eliminates adverse reactions of parasitic capacitance between roller electrodes, enabling more precise position tracking.

・Proven wheel positioning algorithm is included in low cost ROM to free up programmable memory.

・ Position resolution of up to 1000 points can be achieved.

If you are concerned about the electrical noise robustness of your sensor, the MSP430FR2675 and MSP430FR2676 microprocessors have the following features to simplify your EMC certification:

• A frequency hopping oscillator that is immune to conducted and radiated noise.

• Hardware accelerated post-processing to free up CPU resources.

• Simple configuration and tuning using TI’s CapTIvate Design Center tool.

・

Improve your product quality by leveraging capacitive touch sensing in the user interface, and consider using a touch scroll wheel to reduce touch points.

Other resources

• Evaluate slider and wheel sensor application possibilities by purchasing capacitive touch self-capacitive button, slider, wheel, and proximity sensor boards; capacitive touch MSP430FR2676MCU board; and MSP430 CapTIvateMCU programmer.

・ Quickly and easily generate slider and wheel sensor patterns suitable for product dimensions using the scripts provided in the TI application report “Automating Capacitive Touch Slider and Wheel PCB Design Using OpenSCAD Scripting”.

See the application report “Capacitive Touch Gesture Software and Tuning.”

The Links: SKIIP26AC126V1 MG75J2YS50