Reducing EMI, improving density and integrated isolation are the three major trends in power supply development in 2019

“There is no doubt that power supplies have become increasingly important topics in terms of regulation, transmission, and power consumption. People expect product features to become more diverse, more powerful, smarter, and more cool in appearance. The industry sees the importance of paying attention to power-related issues. Looking ahead to 2019, three broad issues will receive the most attention, namely: density, EMI and isolation (signal and power).

“

Author: Jeff Morroni, Director of Power Management, Kilby Laboratory, Texas Instruments

There is no doubt that power supplies have become increasingly important topics in terms of regulation, transmission, and power consumption. People expect product features to become more diverse, more powerful, smarter, and more cool in appearance. The industry sees the importance of paying attention to power-related issues. Looking ahead to 2019, three broad issues will receive the most attention, namely: density, EMI and isolation (signal and power).

Achieve higher density: Put more power management into a smaller space

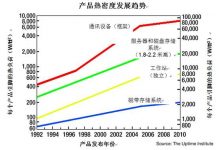

Due to the significant reduction in IC lithography process and the operating power of each function, more functions and gates can be integrated on the chip, and the overall power demand for the finished product is growing rapidly, as shown in Figure 1. Some processors can now consume hundreds of amperes of current, and can rise from a low current state to a fully activated state in less than a microsecond. It is not a joke to achieve the density target of “kilowatt-level power in a coin-sized area” by reducing losses and improving thermal performance.

Figure 1: The development trend of product heat density from 1992 to 2010.

The problem is not only about managing power and the resulting power consumption. Because of the basic I2R loss, even the apparently “negligible” resistance in the power load path has become a major obstacle to effective power delivery: at 200 A, only 1mΩ of lead/wire resistance can cause 0.2 V IR drop and 40 W loss. In addition, because it can be placed close to the load, there is a dilemma when using a smaller converter. This aspect helps to reduce wiring loss and noise pickup, but it also becomes a heat source near the load, causing the temperature to rise.

Trends related to power density: A single “magic bullet” may not be able to solve the density problem. The solution will include interdisciplinary improvements that will lead to:

・Higher frequency switching;

・Move the power management function (or its Inductor) under the processor heat sink;

・Higher rail voltage, such as 48 V, to minimize IC voltage drop;

・New package type;

・Integrate passive components on the chip or package.

Reduce EMI: emission leads to performance uncertainty and rejection of adjustment

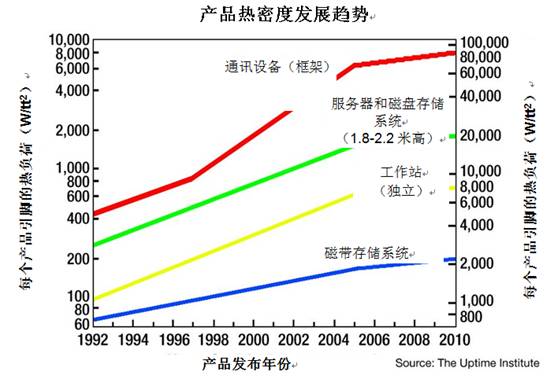

Figure 2: Noise comparison between disabling and enabling spread spectrum.

As Electronic products expand more widely and more deeply into mass market applications, reducing EMI has become a bigger problem, as can be proven by a quick understanding of today’s cars. In fact, due to the difficulty in suppressing AM band EMI, some electric vehicles/hybrid vehicles no longer provide AM radio options. Of course, EMI in cars not only affects the radio, but also affects mission-critical ADAS (advanced driver assistance system) functions, such as adaptive cruise control radar.

For designers, the challenge of EMI is that it is usually more of an art than a science. Modeling is a difficult problem, and its solution usually requires trial and error to reduce it to the required maximum. In addition, EMI is not a single entity, but has different sources, paths, and appearances. For example, usually lead wiring and PCB layout will produce stronger radiated EMI, while converter design and passive filter networks produce stronger conducted differential mode EMI.

Trends related to EMI: Solutions such as passive filters are available and can be very useful, but they can only reach a certain level in the area where size, weight, and cost can be reduced. The greater opportunity lies in how IC suppliers solve EMI problems from the source, so as to provide better results and enhance ease of use to meet the necessary compliance standards.

These solutions detailed the basic principles of noise and layered noise reduction techniques:

・Increase the use of spread spectrum technology to diffuse noise energy, thereby reducing its peak value in the entire spectrum;

・Packaging, including integrated passive components, can reduce the parasitic effects of voltage spikes and ringing when switching;

・Modulate the gate drive of the power device to reduce the dV/dt rotation that generates noise without affecting efficiency.

Reinforced isolation: ensure that there is no current path between point A and point B

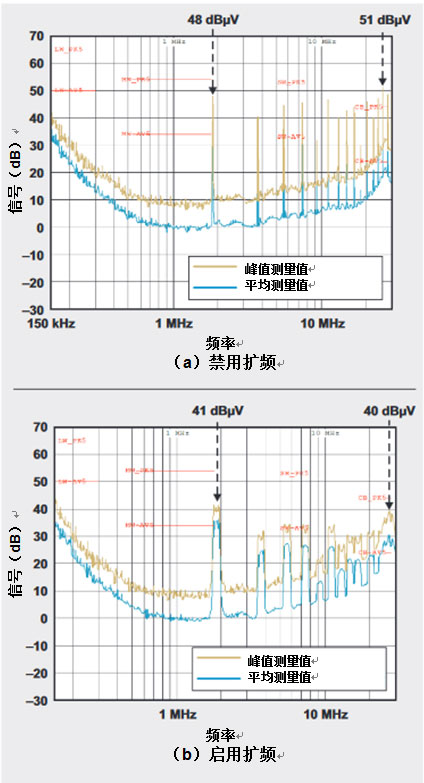

Although electrical isolation technology has been used for many years, new engineers usually know little about it. In short, it provides a barrier so there is no ohmic (current) path between the input and output stages, but allows power and signal energy to pass through the barrier. Isolation can be achieved by various methods, including optical, magnetic, capacitive, or small RF coupling, as shown in Figure 3.

Figure 3: Type of electrical isolation.

Galvanic isolation most often becomes one of the following two main purposes. First of all, it provides safety for users of potentially dangerous high-voltage systems. It can ensure that any internal faults in the system cannot affect users. Second, it implements a large class of innovative power system architectures in which there must be no possible common current between the primary side and the secondary side. For example, when one side is grounded, the other side is in a “floating” state where it is not grounded.

People’s need for isolation is driven by various situations, such as factory automation, extensive human machine interfaces (HMI), solar panels, and medical instruments. The higher dV/dt ratings of GaN and SiC power devices also drive challenging isolation requirements.

Trends related to isolation: Isolation can be used only for power rails, signal lines (data) or both. Ideally, IC suppliers can integrate power and data isolation in the same package to ensure safety and reliability. In addition, due to the integrated data and power isolation functions, IC suppliers can better control and design for the stringent EMI standards typical of these applications.

The required isolation level is a major function of the application: 5 kV reinforced isolation is sufficient in many cases and is defined by detailed industry standards.

Due to its excellent Common Mode Transient Immunity (CMTI) performance and data integrity, the use of isolation capacitors for data transmission is a popular method. However, due to the limited transmission power and efficiency, isolation capacitors are not feasible for most power transmission applications. Therefore, when power transmission is required, the magnetic method becomes the preferred solution. Combining these two methods, solutions such as a fully “self-biased” transceiver can be implemented in the same package, with isolated power and data connections. Such product and technological innovations have truly changed the rules of the game in these safety-critical applications.

in conclusion

Advances in power supply functions, components, and transmission are interdisciplinary, because density, EMI, and isolation are closely related. For example, reducing EMI will lead to a reduction in the size of passive filters, resulting in higher power densities. Progress will come from “stacking” innovation, bringing more major technological developments. These include fully characterized wide band gap (WBG) power devices, improved device die thermal interfaces, enhanced passive devices and functional integration, development of advanced process technology and innovative circuit IP.

Texas Instruments (TI), as a leading supplier of power-related components and design support tools, is developing related technologies that promote and support these trends, including materials, processes, topologies, circuits, and packaging.

The Links: P545A06 LM64C15P LCD-DISPLAY