Using ADI’s mSure Technology for Meter Accuracy Monitoring

“Innovations for utility applications are not limited to monitoring hardware devices that consume energy from the grid, but now offer analytics capabilities aimed at understanding meter accuracy that was previously impossible to track in the field. We partnered with Helen Electricity Network, a distribution system operator in Helsinki, Finland, and Aidon, a well-known provider of smart grid, smart meter technology and services in the Nordic region, using Analog Devices’ advanced endpoint-cloud meter analytics solution (using mSure ® technology) Energy Analytics Studio conducted a field trial.The solution monitors the accuracy of deployed meters over the lifetime and detects a variety of

“

By Mika Nousiainen, Juha Lohvansuu, and David Lath, Analog Devices

Innovations for utility applications are not limited to monitoring hardware devices that consume energy from the grid, but now offer analytics capabilities aimed at understanding meter accuracy that was previously impossible to track in the field. We partnered with Helen Electricity Network, a distribution system operator in Helsinki, Finland, and Aidon, a well-known provider of smart grid, smart meter technology and services in the Nordic region, using Analog Devices’ advanced endpoint-cloud meter analytics solution (using mSure ® technology) Energy Analytics Studio conducted a field trial. The solution monitors the accuracy of deployed meters over the lifetime and detects multiple types of electricity theft. Meter accuracy monitoring is particularly relevant to the Finnish market, which is also the focus of this trial.

Figure 1. Pilot equipment deployed in the field.

The value of precision monitoring

Over time, electricity meters deployed in industrial, municipal and residential environments are susceptible to various conditions such as severe weather, unpredictable loads, lightning and more. As a result, the meter’s measurement accuracy can shift or change, resulting in over- or under-billing, spending a lot of time and money to resolve the resulting problems, but failing to identify errors immediately after they occur, or prevent them in advance .

To make matters worse, power companies can lose customer trust due to meter accuracy issues leading to incorrect billing. Today, most power companies are beginning to sample and replace their meters on a regular basis, but this method is not only expensive, but also disruptive to electricity users.

Using a new technology called mSure, the solution can be integrated into each new meter on-site, and the measurement accuracy of each meter is continuously monitored and reported on-site through a cloud-based analytics service. Power companies can use this analysis service to understand the accuracy of all deployed meters, solve meter problems early, quickly replace meters that do not meet the accuracy requirements, and reduce and eliminate meter sampling inspections where regulations allow, so as to play a better role Existing strengths of AMI networks.

Figure 2. Viewing meter accuracy through cloud-based analytics services.

In addition, energy consumption has become more dynamic due to factors such as renewable energy, electric vehicle charging, and consumers’ electricity bills fluctuate more, which can lead to consumer inquiries or complaints. The solution enables utility companies to quickly assess the accuracy of specific meters, avoiding costly on-site inspections, thereby increasing customer satisfaction.

Field Trial Deployment

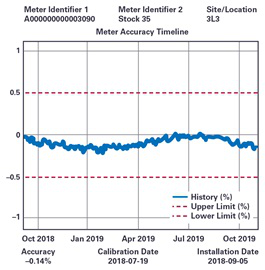

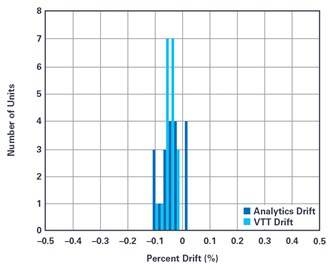

Since August 2018, Helen Electricity Network has viewed meter accuracy information for more than 40 evaluated devices using mSure technology deployed in the field through a cloud-based analytics service. The accuracy of these devices was verified by VTT/MIKES, an independent testing company in Finland. Phase 1: 19 devices in normal use were removed from the site for accuracy testing, and the test results were obtained in October 2018. Phase 2: The 19 devices were subjected to accelerated life testing by VTT/MIKES, and the test results were obtained in November 2019. Test with high precision test equipment to find the baseline accuracy of all devices and to verify the device’s accuracy offset prior to testing. The offset results from the VTT/MIKES test and the implementation of the analysis service after Phase 2 are shown in Figure 3.

Figure 3. Offset range for stage 2 equipment.

Use cloud-based analytics services with locally installed evaluation devices in series with the main electricity meter. The evaluation device shown in Figure 1 uses ADI’s ADE9153B energy metering IC, which integrates mSure technology for advanced diagnostic capabilities. In this way, the meter sends raw diagnostic information to the analytics service, which analyzes it to provide alerts, observe trends, and provide a report on the meter’s health. In real-world deployments, utilities can deploy meters based on the ADE9153B energy metering chip and use analytics services to seamlessly leverage mSure’s technology benefits.

Field test results

In Phase 1, data from the cloud-based analytics service was compared to reference measurements performed by VTT/MIKES, which showed that the analytics service could track an accuracy drift of better than 0.1% for these 19 devices. Strictly grouping all 19 devices, nearly 0% shows minimal drift.

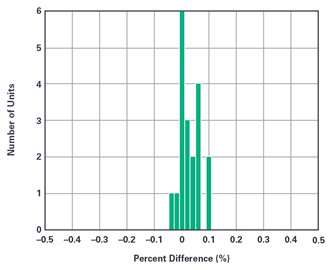

In Phase 2, the meters can be aged for 8 months in an accelerated environment, simulating a situation where the meters will be used for approximately 10 years at an average ambient temperature of 30°C. Phase 2 takes place in a controlled laboratory environment, rather than in the field, in order to accurately assess the performance of the analytical service and to speed up the aging process of these meters. Similar to Phase 1, the 19 devices tracked have an accuracy offset better than 0.1% (as shown in Figure 4), and both the accuracy testing and analysis services show an average negative offset of about C0.05%.

Figure 4. Device differences between analysis service and VTT accelerated life test excursion results in Phase 2.

A meter was also manually aged in the lab to demonstrate the analytical service’s ability to accurately track large excursions. The experimenters changed the impedance by connecting a resistor in parallel with a manganin shunt to achieve artificial aging. VTT/MIKES measured this aging-induced offset and measured -1.91%, while the analysis service determined the meter’s accuracy offset to be -1.96%, a difference of only 0.05%.

Taken together, the Phase 1 field trial demonstrated that the analytics service was able to very accurately track the accuracy of mSure technology-enabled meters deployed in the field to within 0.1%, but the meter offset at this stage was small. In Phase 2, simulating the condition of the meter after 10 years in the field, the accuracy testing and analysis services both showed that the meter was offset in the negative direction and continued to track the accuracy offset with 0.1% error. Field test proof. The combination of mSure technology and analysis services enables the monitoring of meter error excursions with sufficient accuracy to replace meter sampling tests.

The Links: BSM600GA120DLC EVG32240-SMCW