TI reduces the EMI of DC/DC converters by integrating active filters

“A common question that engineers face when designing power systems is how to choose a DC/DC converter: linear or switching converter? Generally speaking, the switching power supply (SMPS) is much more efficient and superior than linear regulators. However, EMI performance is quite different.

“

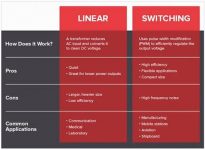

A common question that engineers face when designing power systems is how to choose a DC/DC converter: linear or switching converter? Generally speaking, the switching power supply (SMPS) is much more efficient and superior than linear regulators. However, EMI performance is quite different.

Comparison of linearity and switching, from Advanced Conversion Technology

TI is committed to creating a solution that provides the best of both worlds-high efficiency and minimal EMI.

Switching power supplies are a typical example of engineering compromises. In this case, efficient operation will bring additional EMI problems.

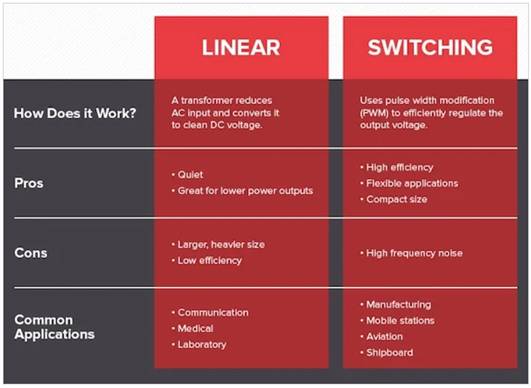

Switching power supplies work by turning on and off semiconductor switches, and use the transient behavior of inductors to boost or buck. Although the switching process produces high efficiency, it also directly leads to EMI problems.

An example of a switching power supply buck converter.Image courtesy of Components101

Ideally, the switch will have infinite impedance when it is open and zero impedance when it is closed. This perfect switching will allow instantaneous changes between these two states.

Unfortunately, exchanges in the real world experience rising and falling times as the state changes. These transitions can cause EMI of the switching power supply, in which the non-linear spikes of the current lead to harmonic components on the high-frequency SMPS waveform. The resulting voltage spikes cause EMI and RFI to exceed 100 MHz.

Integrated active EMI filter

Generally, the measures taken by designers to reduce the influence of EMI in switching power supplies are to use EMI filters, which are usually located outside the switching power supply.

A few days ago, TI released a new synchronous DC/DC step-down controller series, which is said to be the industry’s first integrated active EMI filter DC/DC step-down controller.

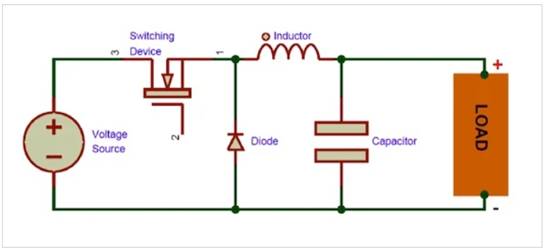

The integrated filter can reduce the overall size of the circuit board by as much as 50%.Image courtesy of Texas Instruments (TI)

The new series is named LM25149-Q1, which uses active EMI filters and dual random spread spectrum technology to achieve 55 dBuV conducted EMI reduction in multiple frequency bands. With integrated filters, design engineers can reduce the size of external EMI filters. According to TI, this allows engineers to reduce the total area by 50%.

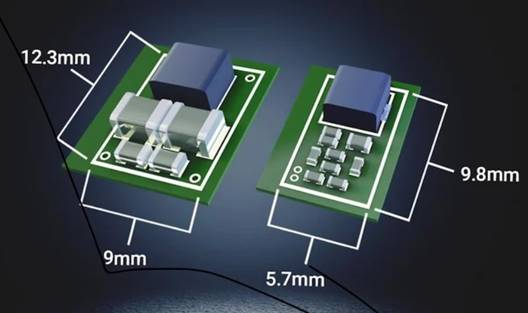

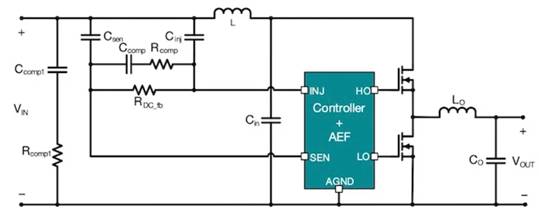

Buck converters use active EMI filters with induction and injection capacitors, and components for compensation.Image courtesy of Texas Instruments (TI)

Another device released in the announcement is the LMQ61460, which reduces parasitic inductance in non-integrated solutions by integrating an internal bypass capacitor, thereby reducing EMI. LMQ61460 works between 3C36 V and can withstand surge protection up to 42 V. Like LM25149-Q1, this IC also uses pseudo-random spread spectrum technology to minimize peak EMI in any given frequency band.

No need to weigh EMI and high efficiency

With the electrification of more fields, it is important to consider the trade-offs of the entire design to achieve the best electrical system. TI tries to do this by creating an integrated switching power supply solution to minimize the impact of EMI, so that applications such as EVs can benefit from high efficiency without worrying about EMI.

The Links: 1DI300Z-100 https://www.slw-ele.com/pht40016.html“> PHT40016